Solid Freeform Fabrication (SFF) is the production of specific parts and components without the need for custom molds and dies. They are manufactured in a freeform process with the use of computer files and carefully controlled equipment to build them layer by layer. Several methods are available, all of which rely on Computer Assisted Design (CAD) and process control tools. Plastics, metals, and resins can be used to make a variety of fully functional and usable three-dimensional components and prototypes.

Four common types of solid freeform fabrication are in use. They start with the generation of a computer file accurately depicting the object to be produced in three dimensions. The computer breaks the object into a series of slices, based on the thickness of the materials that will be used in manufacturing, and feeds them to a production unit. It layers the slices one at a time, building up the object until it’s complete.

One option is selective laser sintering, where a laser fuses powdered materials to make each layer. In laminated object manufacturing, the computer creates a series of layers and attaches them to each other. Stereolithography uses a platform sunk in a pool of resin. The platform is exposed to ultraviolet light to cure a layer, and then lowered so the process can be repeated. As the platform drops, the object takes shape.

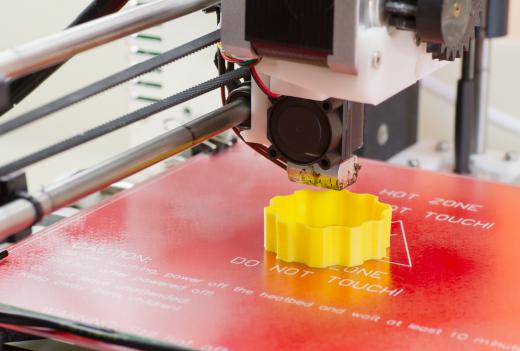

Another form of solid freeform fabrication is fused deposition modeling. This uses heated plastic which is forced through a nozzle to create a layer. Each successive layer builds on the last as it cures, creating a finished solid object. The best production method can depend on the materials used and the kind of object being manufactured.

Universities use solid freeform fabrication in research and development, where engineers also work on new technologies to make the process faster and less expensive. This can include research into entirely new production methods, some of which are intended to make it accessible to end consumers. Instead of purchasing products, for example, consumers could buy files that feed to their personal three-dimensional printers and create an instant output.

Manufacturers have a use for this technology in the creation of prototypes and custom components. Creating unique tools, for example, can be much more cost-effective with this method. There are also military applications for solid freeform fabrication, with ongoing research and development in defense contexts. Careers in this field are highly varied, and a college degree is usually required to work in solid freeform fabrication.

Ever since she began contributing to the site several years ago, Mary has embraced the exciting challenge of being a About Mechanics researcher and writer. Mary has a liberal arts degree from Goddard College and spends her free time reading, cooking, and exploring the great outdoors.