Ductility is the ability of material, such as steel, to be drawn out into thin wires or flat sheets without pulling apart or breaking. Materials that are extremely ductile can be stretched thin without cracking and losing their strength. This is a desirable quality, especially in metals. Manufacturers want materials that will not break even when thin pieces are required.

To measure a material's ductility, the tester typically takes a measurement of the material's tensile strength. Tensile strength examines how far the material can stretch without breaking. This ability is similar to malleability, though they each have a slight difference. Instead of measuring tensile strength, or essentially how far the metal can stretch, malleability measures how much pressure a material can take without breaking or cracking. This type of pressure is known as compressive force.

A metal can be both ductile and malleable, or it can be only one. For example, a metal might have both, meaning it holds up well under pressure and can be stretched into thin wires. Another metal, however, might have the ability to hold up well under pressure, but begins to break apart when stretched. This second metal would be malleable but not very ductile.

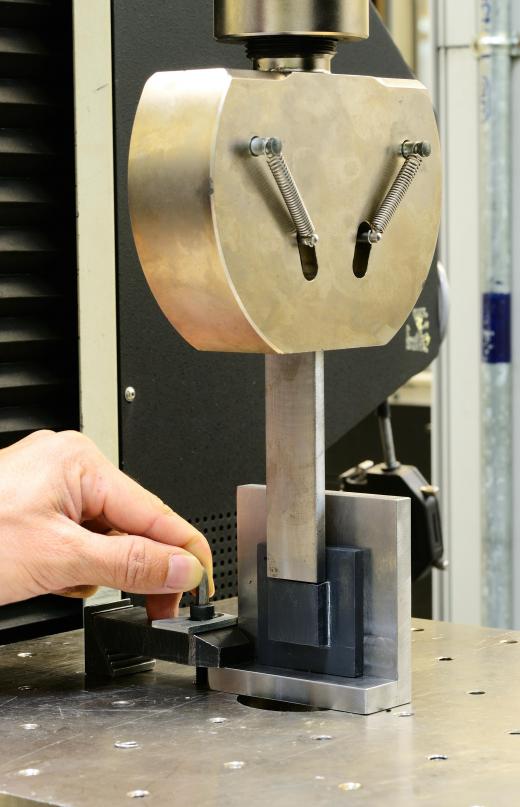

When the ductility of a material needs to be determined, a commonly used method is the bend test. A wire or thin sheet of the material is placed in a machine that applies force to a certain spot at a specific angle. A specific amount of force is exerted onto the material for a given amount of time. Afterward, the material is checked to see how well it held up during the test. The more ductile the material, the better it will do on the bend test.

Gold and silver are ranked as the most ductile metals. While steel is a common metal used in manufacturing and engineering, its ability to stretch can change depending on the elements in the steel itself. Though metals have a certain level of this ability, it can be increased or decreased based on what the metals are made out of and how they are created.

Metals that have a high ductility can be made more brittle. This usually occurs from a change in temperature used on the metal. Cold temperatures can create less ductile metals. When choosing between two metals that are the same in other respects, a manufacturer will typically choose the metal that is more ductile to use in his project.