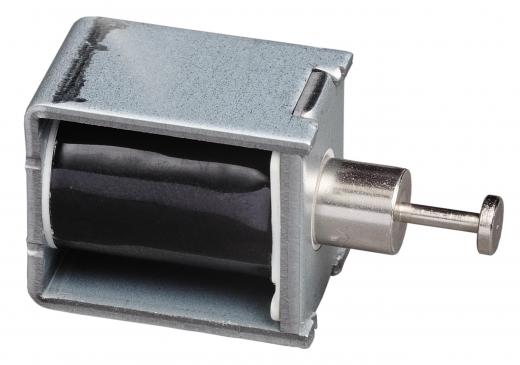

A solenoid driver is a device most often responsible for regulating solenoid activity. In general, solenoid drivers work through circuitry that can be programmed to maintain optimal solenoid operating conditions. There are several applications for these devices, often in industrial processes that cause high stress on the different types of solenoids. Variations of these devices typically accompany different voltages and solenoid designs. In many cases, a solenoid driver can offer some significant advantages while having few disadvantages aside from initial cost.

The purpose of a solenoid driver is typically to control electrical signals. To achieve this goal, direct or indirect connections to solenoid mechanisms allow the circuitry to regulate voltages. Additionally, the circuitry can interface with a computer that can enable user interaction and process programming.

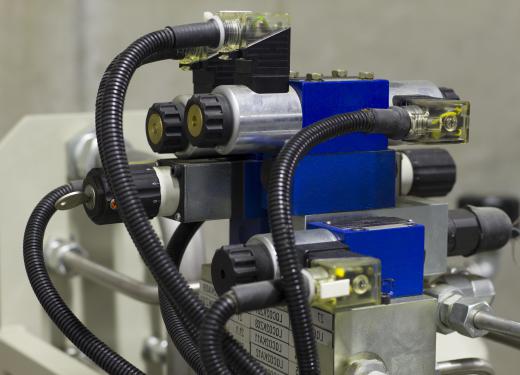

Several applications for a solenoid driver make it an important part of many industrial processes. For example, some solenoid drivers might reduce the voltage once a solenoid has been activated to reduce electrical stress while still maintaining an activated device. Some solenoid drivers might be used to control multiple solenoids that have to work in unison. Others might be used to monitor and control hydraulic or pneumatic devices that require precise solenoid voltages over time.

Variations might include solenoid drivers meant to handle high or low voltages. The differences in these might include safety mechanisms and robust circuitry designs when necessary. Other variations can include direct current (DC) and alternating current (AC) solenoid drivers, which will generally have different designs based on regulating those kinds of power. In some cases, the circuitry may be exposed on a solenoid driver and also may be enclosed in the case of high-use solenoid variations.

Advantages to using a solenoid driver generally come from improved solenoid activity, especially over time. By regulating the voltages required to maintain normal operations, a solenoid driver can extend the life of solenoids by reducing electrical stress. They also can provide a buffer between direct power sources, which can further reduce the stress. Additionally, the ability for users to interact with the solenoid can positively affect the service life.

Disadvantages are generally considered few besides initial cost. Installation may be difficult in pre-existing systems, though integrating a solenoid driver is typically standard to newer devices. Another disadvantage is that circuitry can be difficult to repair without specialty equipment, and many solenoid drivers become disposable after time. This can drive the cost down but also can produce wasted circuitry that is difficult to recycle.