Solenoids are machine parts, so they are often subject to wearing out and breaking. The best tips for solenoid repair include diagnosing the problem — being aware of common problems can help — checking the wiring, checking for debris that might interfere, replacing faulty parts and keeping in mind anything specific to the particular type of solenoid. Many times, solenoid repair might mean replacing an entire piece of equipment rather than individual parts, largely because of the interconnected nature of those parts. As a result, a broken solenoid can be frustrating, but these steps should help facilitate the repair process.

A common first step for solenoid repair is to diagnose the problem. One should determine what normal operation should be in terms of electrical output, the reactions of moving parts and the effectiveness of the solenoid. Using a voltage meter can be helpful, though one of the best tips is to ensure that it is possible to test without personal risk of shock. It also may be helpful to test the machine within normal working parameters. A user’s manual for the related device can be helpful in diagnosing problems.

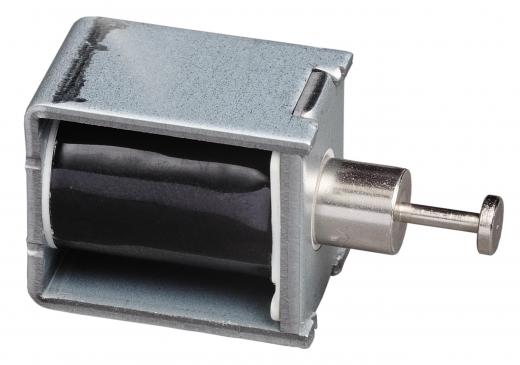

Typical solenoid problems include corrosion, worn-out machine parts and disconnected leads. The metal of the solenoid or the surrounding machine can corrode over time, especially with older machines and those with less of a barrier between the solenoid and external influences. Moving parts in these machines tend to wear out over time, as well, and solenoid repair might include replacing some of these parts to make the solenoid work properly. Additionally, solenoids depend on electricity and, over time, the leads that provide the solenoid with current can wear out.

For instance, the wiring and electrical connections related to a solenoid can fray or otherwise break. One of the best tips for solenoid repair is to track any wires or electrical connections to their source to ensure they are complete and working. Often, the actual solenoid can be in good working shape while the supporting electrical connections are broken or otherwise ineffective.

Another one of the best tips for solenoid repair is to check for debris that might interfere with normal solenoid operations. For example, in solenoids used for water pumps, moisture and debris from the water can work their way into the solenoid chamber over time. Many times, solenoid repair can be as simple as removing this debris, letting everything dry out, and putting everything back together again. As with water pump solenoids, other solenoids often have problems specific to their configurations.