A hard hat is a piece of safety gear which is designed to protect the skull and soft tissue of the face. Hard hats are required at most construction sites, where workers are at risk of injury from falling objects, electrical shock, falls, splash back, and a variety of other workplace hazards. Although the hard hat was only introduced in the early part of the twentieth century, it rapidly became required gear on the job site, and hard hats have saved untold numbers of lives since the first “Hard-Boiled Hat” was introduced in 1919.

The original Hard-Boiled Hat was the brainchild of E.D. Bullard, a pioneer in workplace safety who was concerned about the large number of catastrophic accidents that miners in California experienced. He wanted to refine the soft leather hats worn by miners, and developed a hat made from rigid steamed canvas stretched over a suspension system that lifted the hat from the head. The hat was known as the Hard-Boiled Hat because of the manufacturing process, and was coated in black paint before being shipped for sale.

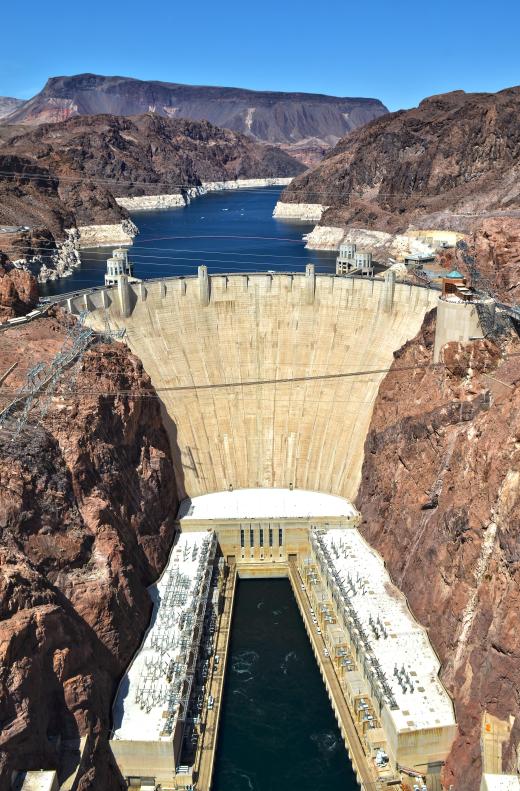

The concept of protective head wear quickly caught on, and the first official hard hat area in the United States was on the site of the Golden Gate Bridge, opened in 1937 to great acclaim; partly because of the low incidence of injury and death during the construction of the bridge. Workers on the Hoover Dam also wore hard hats, and in 1938 the E.D. Bullard Company produced the first metal hard hat, following with a fiberglass version in the 1940s. These materials were stronger, more durable, and more protective, and workplace injuries were greatly reduced as a result.

In the 1950s and 1960s, thermoplastics became more affordable than metal or fiberglass, and the lightweight, sturdy plastic hard hat was born. The Bullard Company was the first to use injection molding to create hard hats, and continued to make innovative suspension systems to support the hard hat on the head while ensuring that it would not slip or fail in the event of a workplace in accident. In the 1980s, in response to requests by several major clients, the Bullard Company also developed specialized hard hats for emergency personnel, climbers, and others in need of lightweight, sturdy protective headwear.

A basic hard hat has a light weight, rigid shell attached to an internal suspension system which keeps the hard hat snug on the head. Some designs also integrate visors to shade the eyes, welding masks, clips for lamps, and insulation to protect from electrical shock. Many also integrate space for ear protection, another frequent requirement on the job site. When worn properly, a hard hat protects the skull and soft facial tissue, and they are required on most job sites for all individuals, even those who are simply visiting, to reduce the risk of construction related injuries.

Hard hats classically come in white or yellow, but rarely remain a solid color for long. Many construction workers decorate their hard hats with stickers commemorating job sites and union memberships, partly to help distinguish which hard hat belongs to whom. The hard hat has become part of the iconic image of the American construction worker, thanks to its ubiquitous presence on the job site, and the term “hard hat” is sometimes used in slang to refer to construction workers.

Ever since she began contributing to the site several years ago, Mary has embraced the exciting challenge of being a About Mechanics researcher and writer. Mary has a liberal arts degree from Goddard College and spends her free time reading, cooking, and exploring the great outdoors.