The medicine tablet manufacturing process involves several main steps, including blending or granulation of materials, lubrication, pressing, and film coating. Different medicines will require different tablet manufacturing processes because sometimes adequate homogeneous mixing requires additional steps. Tablets require the proper dosage of the active ingredient as well as proper mixing, which includes evenly distributed ingredients in appropriate amounts.

One of the simplest strategies to make tablets is to blend the ingredients together. Blending processes generally occur when the ingredients are in powder form, and they require machines to mix them at high speeds. If blending techniques are not adequate, granulation processes will be implemented in the medicine’s tablet manufacturing process.

The two main forms of granulation are wet granulation and dry granulation. During a wet granulation process, the powdered ingredients are combined with a liquid, known as the binder. The binder can be either organic or aqueous and it should avoid inactivating the drug, and should also be carefully measured to ensure the best consistency and granule strength. Once mixed, the granules undergo a sieving process to strain out oversized aggregates, followed by a drying process.

Dry granulation is also frequently used in a tablet manufacturing process, and it involves creating granules using compaction methods. It yields smaller granules than wet granulation, generally costs less, and it is mostly used for materials that react negatively to moisture. After either granulation process, the medicine is lubricated with a powdered form of common fatty acids, such as stearic acid.

Once the powder or granules have been formed, the materials are compressed into the tablet form in a compacting or pressing machine. This usually involves both a pre-tamping and a compression stage, which are accomplished at high speeds ranging from 50 to 500 milliseconds. Several factors can negatively impact tablet formation, including uneven distribution of weight or powder density, stickiness and lack of lubricants, and poor machinery, which could potentially chip or damage newly formed tablets.

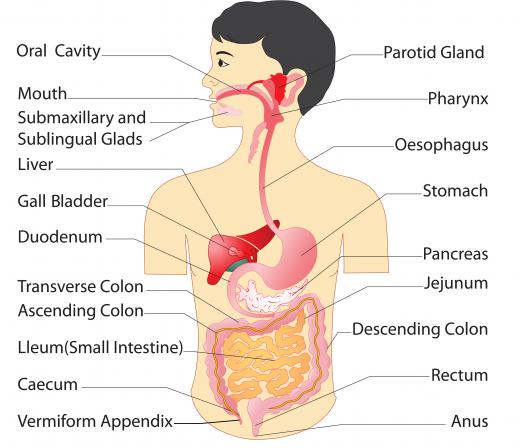

Tablets are also often coated in a polysaccharide blend for protection and improved taste. Not only do coatings protect the drug and lengthen its shelf life, but they also protect the lining of the esophagus and stomach from certain harsher medications because tablets that take longer to dissolve will lessen stomach irritation. Many tablets also contain grooves or markers that enable pill-splitting to occur. Specialized machines are able to divide previously manufactured tablets to vary the dosage in each pill.