Tempering is a heat-based process used in both the production of finished metals, alloys, and glass, and in chocolate making. Though tempering chocolate is quite different than tempering steel or glass, most tempering projects involve heating a substance a second time in order to create a finished product that is less brittle and more malleable than its prior form.

With steel, the first firing process that creates hardening often leaves the alloy too brittle for most uses. In order to turn steel into a more usable form, such as for knife blades, tempering must be done to both relieve some of the internal stresses and brittleness caused by initial heating. Tempering requires the alloy to be reheated, but to a lower degree than its original heat treatment. Knowing the correct temperature to temper a steel object depends on its intended use; there are many different grades of temper that may be required for different objects. While lowering the brittleness, however, the process also weakens the steel somewhat.

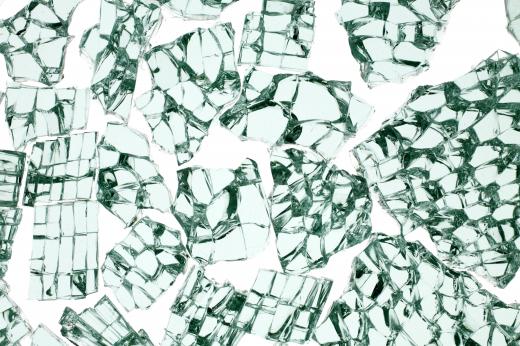

Tempered glass is used in most automobiles, where more durable glass is needed to stand up to daily stresses of driving. Tempered glass is made by exposing glass to a heat process followed by rapid cooling. According to some experts, this increases the strength of the glass tremendously, making it far safer for high-stress environments. The rapid cooling process does create extremely weak edges, compared to the strong center of the pane, meaning that the tempered glass must be filed or ground down to create uniform strength.

Any confectioner will assert that tempering is necessary to create the best chocolates. Chocolate is neither glossy nor particularly smooth in its natural state; as melted chocolate cools and reforms, it creates a crystalline structure that can be manipulated by managing the cooling heat. Untempered chocolate will cool into a gritty-textured block that may be gray, streaky, and brittle to the touch. Keeping the chocolate at the temper heat until it is poured or used will help it cool to a smooth, glossy, malleable form with a higher melting temperature. Depending on whether dark, milk, or white chocolate is used, the temperature needed to create tempered chocolate will vary.

In any form, tempered material changes its appearance and characteristics because the fine structures of the material are altered. Despite this relatively sophisticated concept, the temper process has existed for centuries longer than the science that describes it. The origin of tempered products in nearly every industry is difficult to track down, but the effectiveness and utility of this unique process continues to influence manufacturing of a variety of products.