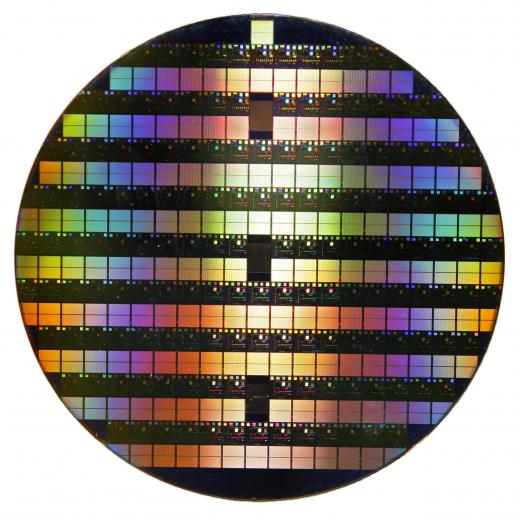

Optical lithography is a chemical process usually used in making computer chips. Flat wafers, often made from silicon, are etched with patterns to create integrated circuits. Typically, this process involves coating the wafers in chemical resist material. The resist is then removed to reveal the circuit pattern, and the surface is etched. The manner of removing the resist involves exposing the light-sensitive resist to visible or ultraviolet (UV) light, which is where the term optical lithography came from.

The main factor in optical lithography is light. Much like photography, this process involves exposing light-sensitive chemicals to beams of light in order to create a patterned surface. Unlike photography, though, lithography usually uses focused beams of visible — or more commonly, UV — light to create a pattern on a silicon wafer.

The first step in optical lithography is to coat the wafer’s surface in chemical resist material. This viscous liquid creates a light-sensitive film on the wafer. There are two types of resist, positive and negative. Positive resist dissolves in developer solution in all the areas where it is exposed to light, while negative ones dissolve in areas that were kept out of the light. Negative resist is more commonly used in this process, because it is less likely to distort in the developer solution than positive.

The second step in optical lithography is to expose the resist to light. The goal of the process is to create a pattern on the wafer, so the light is not emitted uniformly over the entire wafer. Photomasks, often made of glass, are typically used to block the light in areas that the developers do not want exposed. Lenses are also typically used to focus the light on particular areas of the mask.

There are three ways that the photomasks are used in optical lithography. First, they may be pressed against the wafer to block the light directly. This is called contact printing. Defects on the mask or the wafer may allow light onto the resist surface, thereby interfering with the pattern resolution.

Second, the masks may be held at close proximity to the wafer, but not touch it. This process, called proximity printing, reduces the interference from defects in the mask, and also allows the mask to avoid some of the extra wear and tear associated with contact printing. This technique can produce light diffraction between the mask and the wafer, which may also lessen the precision of the pattern.

The third, and most commonly used, technique for optical lithography, is called projection printing. This process sets the mask at a greater distance from the wafer, but uses lenses between the two to target the light and reduce diffusion. Projection printing typically creates the highest resolution pattern.

Optical lithography involves two final steps after the chemical resist is exposed to light. The wafers are typically washed with developer solution to remove positive or negative resist material. Then, the wafer is typically etched in all the areas where the resist no longer covers. In other words, the material 'resists' the etching. This leaves parts of the wafer etched and others smooth.