Direct manufacturing (DM) — also known as additive or rapid manufacturing — is a process that creates a solid, three-dimensional (3D) object from liquid or powder. This may be accomplished by striking the substance with a laser or other form of beam, such as an electron beam, or directing it in molten form through extremely narrow nozzles. Digitized designs, such as those created in Computer-Aided Design (CAD) programs, are fed into a computer that controls the process and creates the end product.

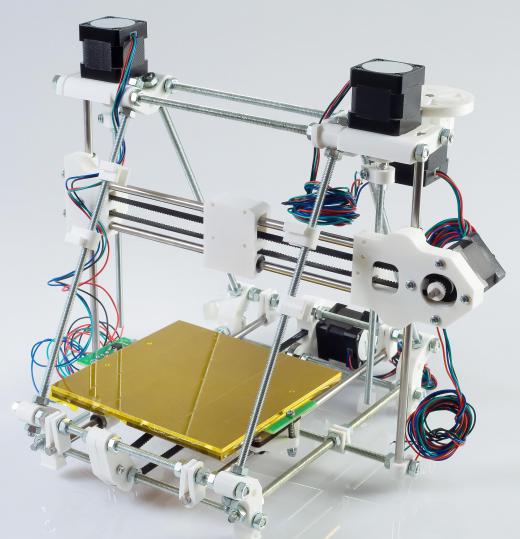

Direct manufacturing may be simplistically characterized as “3D printing.” The operation may resemble that of a classic ink jet-style printer, but it works in three dimensions. Like traditional printing, once the design is input to the computer, the rest of the process is handled without human interaction.

The types of direct manufacturing can be divided into two main categories: those in which molten material is laid down and those in which layers of material are acted upon. In the first case, molten material — usually a plastic — is extruded through nozzles, none much wider than a human hair. The filaments are laid-down, one layer at a time, according to the CAD drawing, with a typical layer measuring 0.005 inches (0.0127 cm) thick.

In the case of material that is acted upon, a thin layer of powder is laid down, usually by a roller. Then a layer of the CAD drawing is etched across the powder with a laser or other energy beam. The powder particles are fused in the shape of the beam’s path, creating a single layer of the drawing. The process is then repeated until the item is finished.

Specialty or limited manufacture items are often best-suited for direct manufacturing, such as prototypes or pieces for spacecraft or military aircraft with unusual geometry. In the creation of end-user items, some companies working with DM methods claim that the process is competitive with traditional machining and injection molding techniques. When deciding between DM and another manufacturing process, manufacturing volume, design complexity, and probability of change should be considered.

Because of the prohibitive costs of molds and machined parts needed for traditional manufacturing, direct manufacturing may be well-suited to short or uncertain production runs. It can be used for other products once the intended run is finished. For very complex designs, DM may be able to create single-piece items that would be difficult or even impossible to create with most other manufacturing methods.