Dimensional metrology is the measurement of size and distance, along with the study of measurement techniques and the development of new technology, to increase the accuracy of measurements. Humans have been on a quest to measure objects and make those measurements as precise as possible for thousands of years, as evidenced by numerous objects in the historical record that show how previous societies measured and recorded measurements. Several organizations dedicated to measurement and standardization have dimensional metrology divisions.

One aspect of dimensional metrology is the development of standardized units for measurements and specific practices for taking and recording measurements. The metric system, for example, is a standard used in many regions of the world to measure dimensions. Standard techniques and practices are important, especially when it comes to declaring measurements on technical documents. Any reader should know how the measurements were performed so she can precisely replicate them.

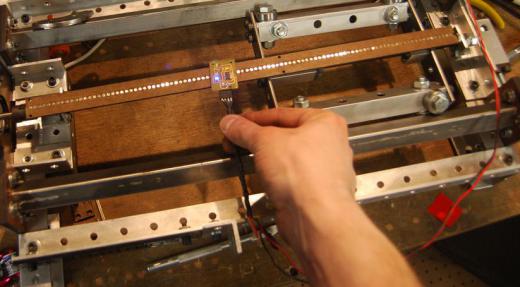

The development of tools for measurement is another component of dimensional metrology. Devices for measuring can include everything from tape measures to levels. It is possible to measure numerous angles and components of a product, from the holes tapped for the screws to the angle of the curvature on the lid. Dimensional metrology allows for very precise measurements on projects with minimal tolerance for error, like machined parts that must fit exactly into a system for functionality.

The actual practice of measuring includes not just taking measurements in a standardized way with the right instruments, but also maintaining good conditions for measuring. Maintenance of measuring equipment is important, as is regular calibration to ensure that measurements are accurate. A small margin of error can become large over time, especially on a major project. Manufacturers must develop high performance measuring tools along with methods for calibrating them and checking measurements for accuracy.

Many researchers in the field of dimensional metrology are engineers, specializing in a variety of subtopics. Companies that manufacture measuring supplies can also produce instruments for collecting and recording other kinds of data. These can include mass spectrometers for analyzing the chemical makeup of products, scales for assessing weight, and tools for measuring volume, among many others. Working in this field requires excellent observational skills, a sharp attention to detail, and the patience to refine projects until they are perfect. Math and science skills are also critical, as dimensional metrology relies heavily on formulas and advanced scientific concepts for precision. Specialists can work for private companies, organizations that set and maintain standards, and government agencies.

Ever since she began contributing to the site several years ago, Mary has embraced the exciting challenge of being a About Mechanics researcher and writer. Mary has a liberal arts degree from Goddard College and spends her free time reading, cooking, and exploring the great outdoors.