A solenoid connector is a cable termination device used to join the coil leads of a solenoid to its power supply source. In most cases, these connectors are of a standard design and consist of male and female halves that clip securely together. Typically, the power supply side of the connector is a female socket with recessed pins, while the coil side features the male plug. In most cases, these connectors will be of a generic, removable-pin type, although many solenoid applications feature specially-designed connectors. When replacing a broken solenoid connector, care should be taken to ensure that the connector/pin combination is suitably rated to carry the solenoid's operating current safely.

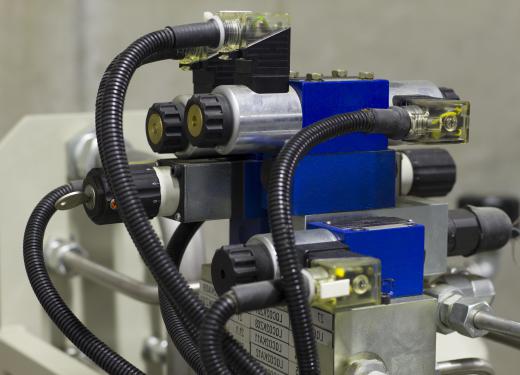

Most solenoids feature sealed coils with short lengths of exposed power supply lead. These leads have got to be connected to the solenoid power source before the solenoid can be used. In some cases, the solenoid is close enough to the control source for the leads to be inserted directly into its output connections. In the majority of applications, however, the power source will be a fair distance from the solenoid and will require control wiring to be routed to its position. A solenoid connector is then used to make a safe, clean connection between the coil leads and the power source wiring.

In theory, for any sort of connection, including connector blocks, soldered connections, or push-in, pre-insulated terminals will suffice when joining solenoid wiring into a power supply circuit. A solenoid connector is, however, the preferable way to make these connections for a number of reasons. First, they create a standardized installation where the replacement of parts requires no modification of existing wiring. Secondly, they ensure tight, clean joints with little or no potential for electric shocks, overheating or short circuits. Non-permanent solenoid connector joints are also desirable from a diagnostic perspective, as they allow a technician to easily isolate the solenoid when testing the circuit for fault locations.

There are a large selection of generic products that are suitable for use as solenoid connectors, including the familiar, extractable pin connectors. Many applications do, however, feature brand-specific solenoid connector types, which may make replacement difficult. In all cases, though, care should always be exercised when replacing a solenoid connector to match the new connector capacity to the solenoid coil operating current. An incorrectly-rated connector can cause the connector housing to overheat and melt, creating a shock or fire hazard.