A rock drill is a drilling device designed specifically for penetrating rock, for use in activities like digging wells, preparing foundations, and mineral exploration. A number of companies manufacture rock drills, often offering a lineup of several models to meet various needs. This equipment tends to be expensive and special training is required to use it. Drills can be leased, and operators can be hired by companies that do not have a full time need for a rock drill and operator.

Drilling through rock presents a challenge because the substrate is very hard. Ordinary drills can be damaged quickly. Rock drills feature especially hard bits made with materials like industrial diamonds, along with lubrication and cooling systems to limit stress caused by friction. The drill can also use an air blower to clear out the drilling hole as the drill penetrates, limiting damage to the drill caused by rock dust and other particulate materials.

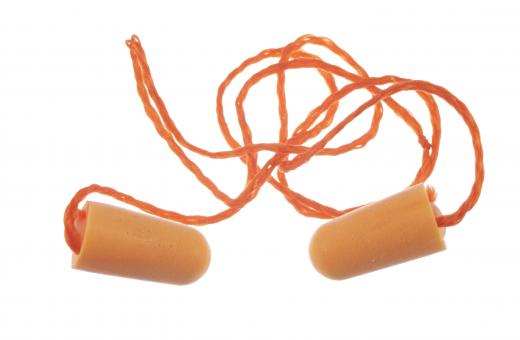

Rock drills can be attached to drilling rigs for jobs when it's necessary to drill very deeply. They can also be manually controlled by an operator, in the form of a pneumatic rock drill with a throttle. In both cases, people must wear appropriate eye, ear, and facial protection when working around the drill. These drills are noisy, and inhaling rock dust or getting it in the eyes can be very uncomfortable. Drilling teams and personnel in the area usually wear facial screens and ear plugs to limit injuries associated with their work.

With rock drills for purchase, people may be able to rent or test several models before making a purchase decision. Drilling needs are highly variable, and since this equipment is expensive, companies usually want to make sure their customers are fully satisfied. In the case of leased drills, people can pay hourly or by the day, depending on the job, and can also request an operator to run the rock drill or provide instruction for people on the job site so they can take over drill operation.

Companies with several models on offer typically have a range of sizes, as well as drills intended for particular applications. A rock drill may be equipped to take core samples for mineral exploration, for example. Safety features such as emergency shutoffs, drills that shut down automatically when no one is touching the throttle controls, and cages around the moving areas of the bit are usually installed on drills. While it is sometimes possible to override safety features for specific applications, this is not generally advised.

Ever since she began contributing to the site several years ago, Mary has embraced the exciting challenge of being a About Mechanics researcher and writer. Mary has a liberal arts degree from Goddard College and spends her free time reading, cooking, and exploring the great outdoors.