A propane solenoid is the actuation component of the valves used as automated or remote flow-control agents on propane gas systems. These units typically are one-piece, integral assemblies that consist of the solenoid component mounted on a brass or stainless steel gas valve. The solenoid components generally are sealed units designed to pose a minimum danger of spark ignition of the propane gas. The propane solenoid and valve assembly usually is mounted in close proximity to the propane source, which decreases the system area that is flooded with gas when the valve is closed. This proximity to the gas source requires careful selection of the correct solenoid and related safety equipment to minimize the risks of explosions and fires.

Propane gas systems that are used in marine, recreational vehicle (RV), domestic and industrial heating applications typically feature at least one isolation valve close to the gas source. In many cases, this is a simple, manually operated valve located on the main outgoing gas line. In some cases, however, an automated or remote cutoff is required, and it supplies gas to the rest of the system only when needed. This is a safety measure that is used to minimize the amount of propane in the system during idle periods. In these applications, a propane solenoid valve is the most commonly used solution.

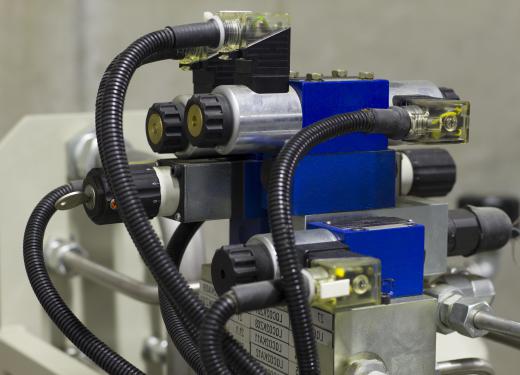

These valve assemblies typically are one-piece units that consist of a brass or stainless steel poppet or diaphragm-type valve assembly with an integral solenoid component mounted on the valve. The solenoid works in the same way as all others and consists of a static coil and a moving, spring-loaded ferrous metal plunger. When the coil is energized with a suitable electric current, a powerful magnetic field is generated around it. This magnetic field attracts the plunger, pulling it rapidly toward the coil. When power is cut to the solenoid, the spring returns the plunger to its neutral, or inactive, position.

The propane solenoid plunger is connected to the valve stem, which, in turn, either seats or opens the poppet or diaphragm, effectively opening or closing the valve. The solenoid assembly typically is enclosed in a sealed plastic or aluminum enclosure with pre-connected coil leads. This minimizes the risk of exposed connections posing a spark ignition risk in the presence of a potentially explosive mixture of propane and air. Although seemingly contradictory to this safety regimen, the propane solenoid valve generally is located as close to the gas source as possible. This is, in fact, the safest location, because it effectively reduces the area of system piping that is filled with gas when the valve is shut.

Any electrical equipment does, however, pose a certain amount of risk of explosion when it is used near flammable gases. For this reason, it is always highly advisable for propane solenoid valves to be kept in good order and correctly rated to prevent overheating of the coil. Other fail-safe devices that are designed to cut off the gas supply in the case of pilot flames being extinguished, such as those that prevent a dangerous build-up of gas, also should be used.