Two different types of equipment are referred to as magnetic drums. One type is a data storage device used in early computers, also known as drum memory. The other is a magnetic drum separator, a tool used in the recycling industry to separate metals from other materials.

The magnetic drum used for computer memory was invented in 1932. It was the main working memory in most computers during the 1950s and 1960s. Core memory, the forerunner of random access memory (RAM), gradually replaced drum memory as the primary memory, though magnetic drums continued to be used as secondary storage for a while.

In the computer industry, a magnetic drum consisted of a hollow metal cylinder covered with a magnetizable material. Read and write heads recorded data on the drum as it rotated by emitting electromagnetic pulses to magnetize tiny spots to record a binary value of zero or one. The same heads could "read" the recorded data by sensing the magnetized spots. A drum surface was divided into tracks and sectors so users could indicate where information should be stored and avoid writing over previous data.

Compared to more modern storage methods, magnetic drums could store a very small amount of data. A drum that was 4 inches (about 10 cm) in diameter and 8 inches (about 20 cm) long could hold about 500 bits. There are eight bits in a byte, the basic unit of digital information, so the drum could hold about 62 bytes. Most computer memory in the early 21st century is measured in gigabytes, a unit of 10^6 bytes. Drum storage was many orders of magnitude smaller than its modern counterparts, but it was the standard type of memory for early computers.

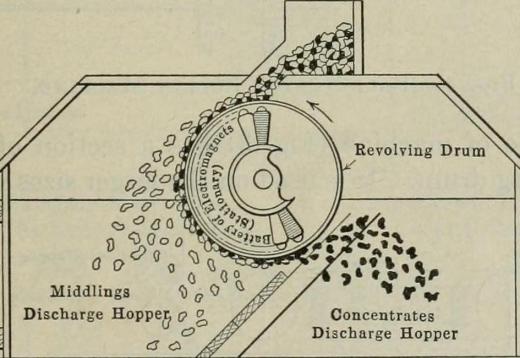

In the recycling industry, a magnetic drum separator may be used to help sort materials. Recycled materials are fed through a chute at either the top or bottom of the drum. The metal scraps stick to the drum, while the other, non-magnetic materials fall out of the drum. The drums are designed so that one side is constantly magnetized, while the other is not; when the metal scraps get to the non-magnetized side, they drop off to a different location than the other materials.

Magnetic drum separators consist of a rotating magnetic cylinder that can capture the metal coming through. To attract the metal scraps, they may use electromagnetic circuits; magnetic fields; or rare earth materials, which are a group of magnetic metals. Magnetic drum separators come in a variety of sizes to accommodate varying volumes of materials.