A hydraulic cylinder produces linear motion and force by using pressurized hydraulic fluid. Industrial machines powered by these cylinders are able to form metals or other materials at a very high force with a relatively small supply of highly pressurized fluid.

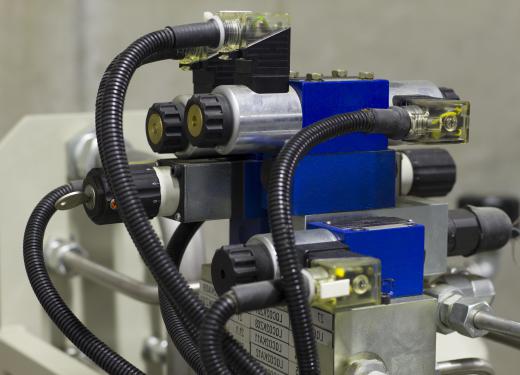

Heavy equipment, such as an excavator, relies on the power of hydraulic fluid. The operator easily controls the pressurized hydraulic fluid with the use of a control valve connected to distributor hoses and tubes. A solenoid valve is the type of valve most commonly used with a hydraulic cylinder as it has a reputation of safety and reliability. Valves not only control the release of fluid in the cylinder, but often mix gases and fluids as well.

A hydraulic cylinder in a car does not connect to a valve as a means of control, but relies on piston-driven hydraulics instead. When the brake pedal is depressed, the pedal pushes on the piston in the master hydraulic cylinder and the slave pistons located at each wheel work together to stop the car.

Hydraulic seals are crucial in relation to the safe functioning of a hydraulic cylinder. Industries that use heavy equipment, such as automotive, aerospace, government, oil, and gas rely on improving hydraulic seal technology. The explosion of the Challenger space shuttle in 1986 was mainly attributed to malfunctioning hydraulic seals caused by low temperatures that solidified the seal's inner material, thus preventing a proper seal.

Worn out hydraulic seals also present safety concerns, but can often be prevented by using a hydraulic cylinder with a smooth inside surface. The outside surface of the cylinder is usually constructed from aluminum, steel, cast iron, or bronze. Cylinder covers hold the piston rod and can be square, round, or custom-designed to fit each specific cylinder.

The simplest hydraulic systems consist of two pistons and a fluid-filled pipe. Pistons used in hydraulic systems are made in one, two, or three pieces depending on the speed and force required by the machine. One piece of heavy construction machinery uses up to eight hydraulic cylinders that may need as much as 100 gallons of oil.

Water hydraulic systems use water as the fluid for the hydraulic cylinder rather than oil. Although water is less expensive than oil, as well as non-polluting, water's low viscosity and poor lubrication qualities require a system designed exclusively for water hydraulics.