Heating and air conditioning ductwork installation requires a number of duct supplies. These duct supplies are most commonly made of sheet metal. The main trunk line is rectangular duct and is joined together with slips and drives. Hangers on the duct can be made from 1-inch (2.54-cm) strips of sheet metal. A plenum is a fitting used to connect this main trunk line to the furnace.

The main supply duct trunk line will have smaller branch supply trunks coming off of it. These branches will deliver the air to each register opening. Branches are usually rigid, round pipe, but they can also be made of flexible fiberglass duct. They are connected to the main trunk line with a takeoff.

A takeoff can be rectangular or round and fits into a hole cut into the ductwork. It has tabs on the end that are to be bent over inside the duct. This holds the takeoff securely in the duct. When using flex duct, it is necessary to use nylon duct straps to secure the duct to the takeoff.

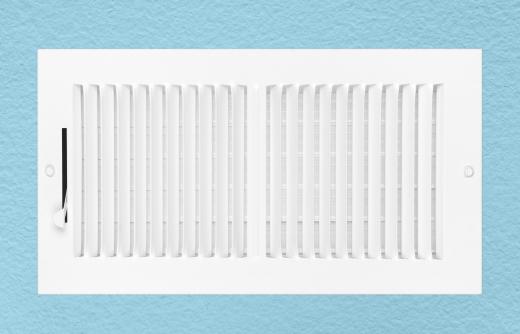

The branch supply trunk lines will run to each of the register openings. Elbows or offsets may be necessary to get the duct to line up in the right spot or to avoid obstacles in its path, and it is sometimes necessary to use a reducer to change the round duct to a smaller size duct. A wye can be used to supply air from one branch duct to two openings. A tee cap closes off the end of a piece of round pipe. A register boot is nailed into the opening and the branch duct will attach to that; the register is then put into the boot.

The return air duct uses the same sheet metal duct supplies. Sometimes, in an effort to cut costs, ductwork is not used for all of the return air; panning is used instead. Panning material is either sheet metal or some type of foil-faced cardboard that is installed over the joist space and the stud space. This creates a tunnel for the passage of return air. A return air elbow is usually used to join the return air duct to the furnace.

Other duct supplies may be necessary to achieve a balanced heating and cooling system. Manual or electronic dampers can be put in the duct to regulate the air flow. All joints should be sealed with a special duct mastic or adhesive. A special aluminum tape also works well, but do not use duct tape. The ductwork should be sealed as it is assembled.