Polycarbonate panels are manufactured out of a hard plastic polymer substance known as Bisphenol A (BPA). Polycarbonate makes an excellent substitute for glass or acrylic, and there are a multitude of uses for panels made of polycarbonates. From the thin plastic lenses found in UV-protective sunglasses, to the thick, bulletproof windows used in security vehicles, these panels play an important role in safety and environmental protection.

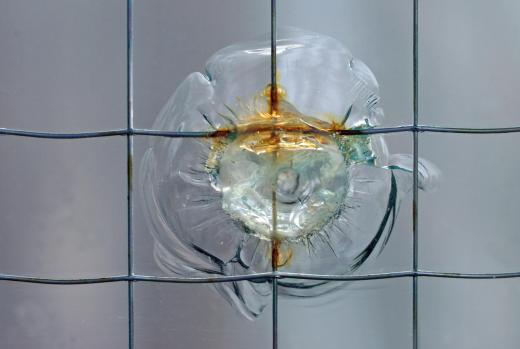

Polycarbonate plastic is moldable, durable, lightweight, flame resistant, shatterproof, and energy efficient. One of its best properties is high-impact resistance, which can be more than 200 times greater than tempered glass. Polycarbonate panels are extremely weather resistant, will not yellow in harsh sun, and recyclable. Ridged sheets of polycarbonate are often installed over walkways, patios and terraces to filter and reduce ultraviolet sunlight, as well as provide rain and snow protection. They are also used in fencing, providing a secure barrier that is practically indestructible.

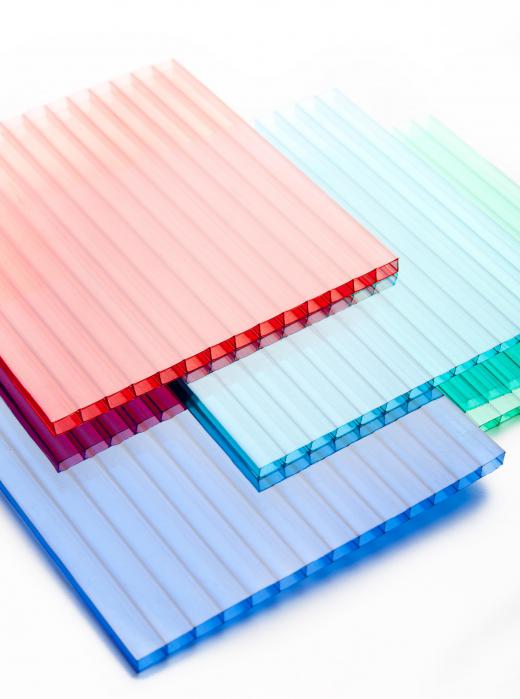

Polycarbonate sheets can be as clear as glass, translucent, or completely opaque, depending on the specific use. The panels can be flat or corrugated, rigid or flexible, thick or thin. Manufacturers offer various grades of glazing for polycarbonate panels designed for exact uses. There are glazing grades that provide static control and fire resistance for use around combustible materials, as well as sign-grade, bullet-resistant, hurricane-resistant, and several other grades of glazing.

Farmers and ranchers have found many good uses for polycarbonate panels. Hard plastic is often used as a structural material for agricultural outbuildings and energy-efficient greenhouses. Pole barns topped with corrugated panels are a common sight on horse ranches and cow farms. Hard plastic panels may also be installed as skylights in a barn to provide a natural lighting source during daylight hours. Additionally, polycarbonate sheets can be installed vertically to act as wall units. Semi-opaque, plastic walls allow light and warmth to reach horses, cows and other farm animals, while obscuring the outside view.

Home decorators have also discovered some pleasing uses for panels made of this type of plastic. BPA plastics are manufactured in a variety of designer colors and textures, and may be cut to fit any size. Plastic panels may be installed as a lightweight room divider, or inserted into kitchen cabinet doors as an alternative to breakable glass. The uses are practically unlimited, and manufacturers and consumers are coming up with new ways to use polycarbonate panels nearly every day.