There are many different types of scaffolding and the precise names and terminology tend to vary from place to place, but in general the main categories are set based on how the structure interacts with the building it’s up against, how it’s constructed, and the type of weight it can support. Independent or birdcage models, which can stand on their own, are some of the most common for small projects and are usually best for use at home; single pole scaffolds, similarly, are generally small and are dependent upon the structure they’re placed against. Window-washers and others who need to move up and down often depend on so-called “swingstage” examples, while the types most commonly seen outside of major construction sites are usually made in either the cantilever or hanging bracket style. All have some inherent dangers, and manufacturers and users alike usually have to adhere to a number of best practices in order to stay safe.

General Properties

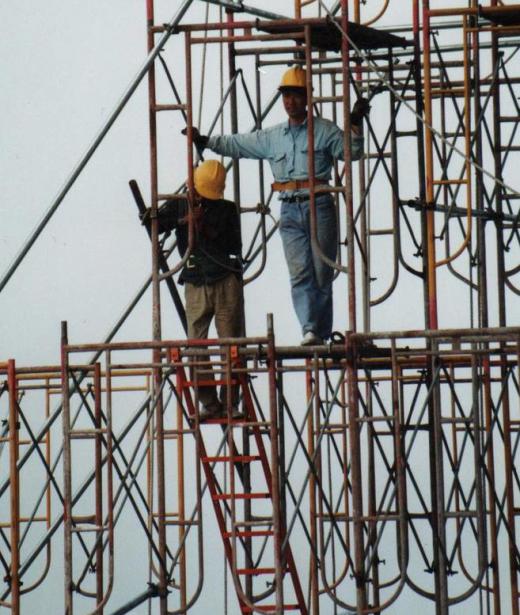

In almost all cases this sort of structure is designed to be temporary, and it’s usually built in such a way as to be more or less easily transportable from one place to the next and relatively basic to set up in any given location. Its main goal is to support workers and equipment as they work on repairs or construction. Most types are made from wood, metal, or both, and usually involve a series of frames and planks that are connected by joints known as bolts and couplers.

When selecting different types, people should usually think about the specifics of their project. A building's design, shape, and location should all be considered, and the ability to adapt to the structure's contours should also be taken into account, particularly if a modular form is being considered. It’s often the case that different types can be used for the same project, just in different ways.

Independent or Birdcage Models

One of the simplest types is known as “independent” or “birdcage.” It usually consists of no more than two rows of vertical poles, often called “standards,” that are connected by horizontal pieces, or “ledgers and transoms.” It is generally intended for use on one level only, like when working on a ceiling. Independent varieties tend to be fairly easy to assemble and move, which can make them a good choice for small, contained projects.

Single Pole Construction

Single pole models, as their name implies, are usually supported by just one pole or row of standards, and also tend to be most popular for more minor projects or tasks that can be completed by one or two workers. These structures are usually completely dependent upon the building or wall against which they are placed for support. They tend to do better outside, whereas independent structures are often more popular indoors.

Suspended and “Swingstage” Examples

Some structures can be raised or lowered on command, usually by a lever and crank or through mechanical means. These are most commonly known as suspend or sometimes swingstage, in reference to the movement of the stage, or platform, where people stand. Window washers for skyscrapers and other tall buildings often depend on these sorts of movable structures, and they can also be useful when it comes to moving tools and supplies from one level or a multi-story construction project to another.

Cantilever

Scaffolds that are attached to a building or other structure at one end only — which is to say, one end is exposed or is left hanging — are frequently referred to as “cantilever.” These are commonly used on the tops of buildings, as well in tight corners and other hard-to-reach areas. They are typically secured with anchors or clamps on one edge, while the other side remains more or less open. People working on this sort of scaffold often wear harnesses or other braces to keep themselves safe in case of a fall or loss of balance.

Hanging Brackets

Many of the most extensive structures are built using hanging brackets, and are often known by this more generic name, too. Hanging brackets are tools that connect different levels to each other, and are most commonly used in scaffolds that are quite tall, sometimes covering the entire sides of buildings and other structures. This system may include horizontal components that are supported by floors of buildings or other structures.

Safety Basics

To ensure safety, scaffolds should always be assembled in accordance with the designer's instructions and the manufacturer’s specifications. Specific rules and safety regulations vary from place to place, but in general any person doing work more than 12 feet (about 3.7 meters) above ground must hold a training and competency certificate to prove safety and emergency knowledge. Apart from the obvious potential for falls, injuries and fatalities can also occur from working close to power lines, mixing and matching components, structural collapse, and falling objects, to name just a few.